- steen@sikteknik.dk

- +45 86 88 87 26

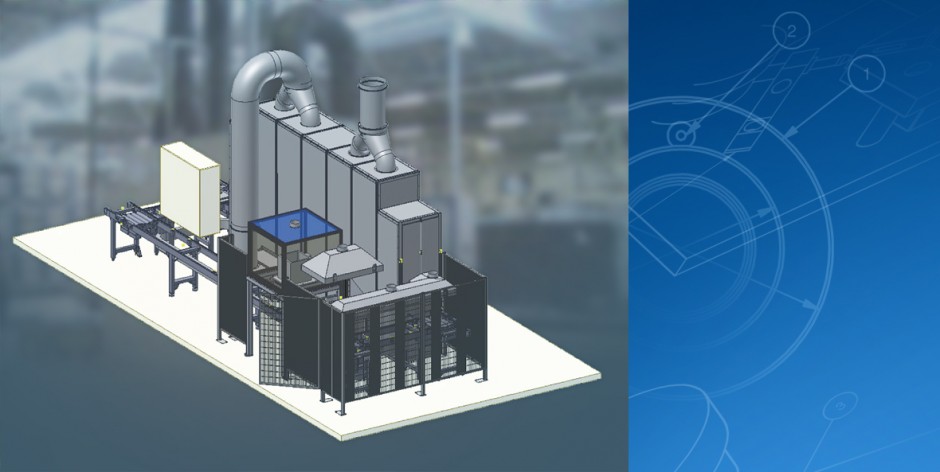

Inductionsheater and assembly equipment for electromotor production

Designed and produced to handle electrical stators from diameter 170 to 250mm, with a weight form 15-60Kg.The task was to automatically mount stators in the motor houses for electromotor production.

The stator and stator house is placed on special designed pallets. The aluminum house is heated to 250oC with in 50 Sec.with a 140Kw induction heater. When the house reach the final temperature a stator is inserted in to the house, after assembly the parts continue in to a double cooling zone. The first zone is cooling with forced air taken from outside the factory; the second zone is cooling with forced air passing through a 150kW cooling radiator. The layout is made forone operator, loading and off-loading is done on the sameworkplace.